Bahasa Indonesia

Bahasa Indonesia English

English

You are here

Industrial Visit: Chemistry Education Student to PT. Yakult Indonesia Persada Sukabumi

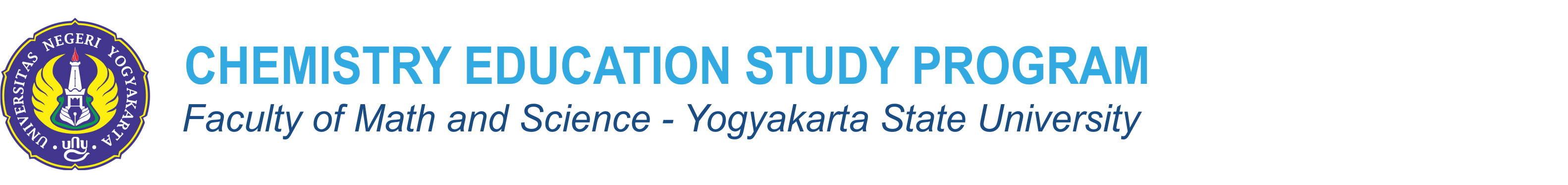

Monday, June 28, 2021, Chemistry Education students has conducting a virtual industrial visit to PT. Yakult Indonesia Persada. Yakult has two main factories in Sukabumi and Mojokerto. The visit was accompanied by Mr. Arbi and Ms. Gusti Pangandian from PT Yakult. The activity was carried out in three stages. First, an introduction to the brief history and advantages of Yakult products, secondly an explanation and a visit to the production department. Next, the students and Yakult held a question-and-answer discussion.

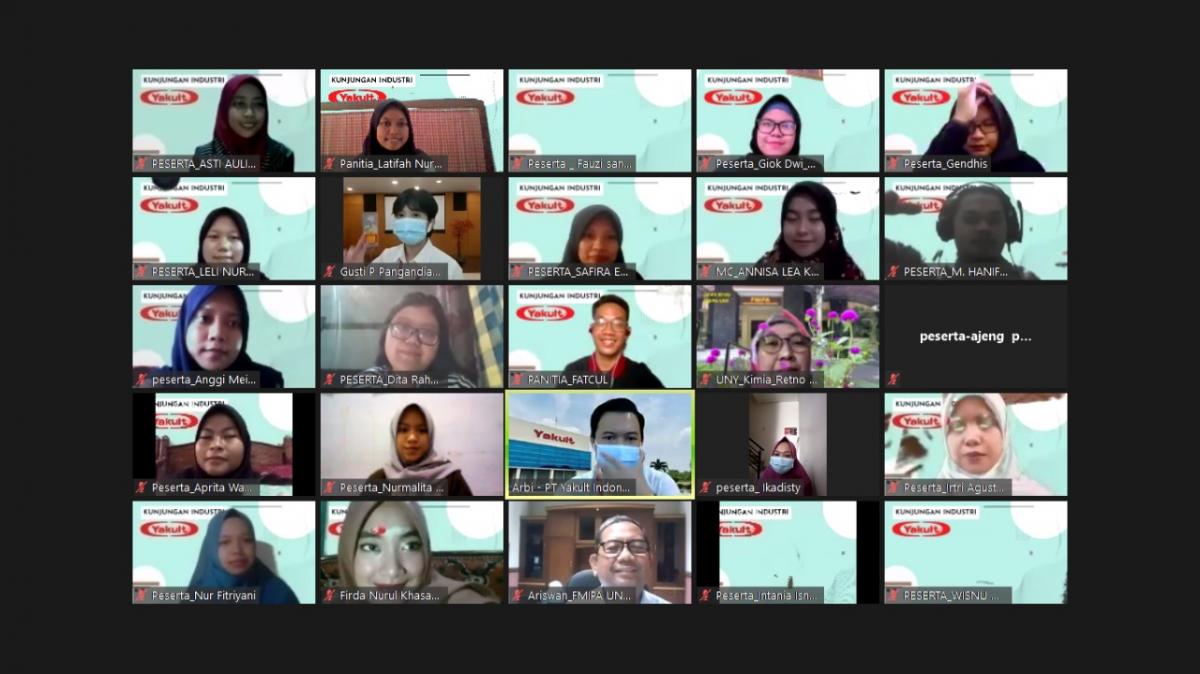

n the introduction stage, students get information about the materials for Yakult production, such as skim milk obtained from Australia and Belgium, dextrose, sucrose as a sweetener for yakult, as well as the main ingredient, namely bacteria L. casei Shirota Strain. The Yakult packaging bottles are made by PT Yakult Indonesia Persada by utilizing polystyrene resin for bottles and aluminum foil for bottle caps. Yakult's bottle production machine is capable of printing 11,000 bottles in one hour. In the production stage, PT Yakult invites students to enter the production section through the production corridor. Here, students get information about the Yakult production process, namely 1) breeding, which is done so that bacteria can multiply, 2) fermentation, 3) mixing, namely the addition of sucrose sugar for the formation of sweetness and UV sterilized water, 4) testing in chemistry, physics, and microbiology laboratories, 5) selector and filling yakult into bottles. If there is a product whose pH is still alkaline, the fermentation stage will continue. Quality Control routinely tests the acidity of the product. PT Yakult Indonesia Persada also pays attention to their products so that they remain of good quality, and are environmentally friendly. Polystyrene resin was chosen for Yakult bottles because it has very small pores so that it allows the bacteria in the Yakult bottle not to be contaminated with bacteria from outside. Their hope is, Yakult can find more environmentally friendly bottle packaging. If there are used plastic bottles from poor production, they will be collected and processed by a third party into household furniture materials. To maintain the quality of yakult in the market, yakult will ensure that expired products are withdrawn and replaced with new products.

The implementation of this industrial visit is expected to provide benefits for students about factory management systems, industrial-scale production processes, and the implementation of chemical science used in industrial processes so that they become provisions for various information on the world of industrial work.

Sistem Informasi

Kontak Kami

Program Studi Pendidikan Kimia

FMIPA Universitas Negeri Yogyakarta

Gedung Dekanat D.07 FMIPA UNY

Kampus Karangmalang Yogyakarta 55281

Telp. (0274)586168 Pes. 115

Email: pend_kimia@uny.ac.id

Copyright © 2024,